Features

Recirc

Systems management

Managing water flow patterns and tank spin

August 21, 2020 By Ron Hill

The way water moves into, within and out of tanks and rearing areas is a subtle but essential consideration for fish husbandry. Water moving through the tank provides self-cleaning, flushing away solid and dissolved waste products. It also distributes oxygen throughout the water column and should provide water conditions specific to the species being reared.

Flow rate

The most important aspect of water flow to the fish farmer is flow rate. Flow rate is the amount of water that flows into a tank over time; that is, how fast water is coming into the tank. If the flow rate is too low, fish health will quickly suffer.

Flow rate must be high enough to keep ammonia and CO2 levels from accumulating. Usually expressed as L/min or ft3/sec, tank flow rate is determined by the desired turnover rate. Turnover rate is how long it takes to replace the entire volume of a fish unit. Turnover rate is specific to the species being reared and rearing density, but one turnover per hour is a good place to start for many species.

For example: a 5,000-liter tank of trout requires a turnover rate of one hour. (5,000 liters/60 minutes = 83.3 L/min) Thus, a 5,000-liter tank requires flow rate to be set at 83.3 L/min to provide one turnover each hour.

Flow rates are, of course, just guidelines and operational requirements will dictate the flow rate chosen. Fish behaviour and oxygen demand often require adjusting the flow rate above or below the calculated turnover rate. As fish density increases, the amount of water in the tank decreases.

Consider the 5,000-liter tank in the example above. If the fish in this tank have a biomass of 200 kilograms, then the volume of water in the tank is 4,800 liters once you subtract the water displaced by the fish. As density increases, waste production increases, but actual volume decreases. Increased flow is needed to keep up with the metabolic demands of the fish.

Spin Rate

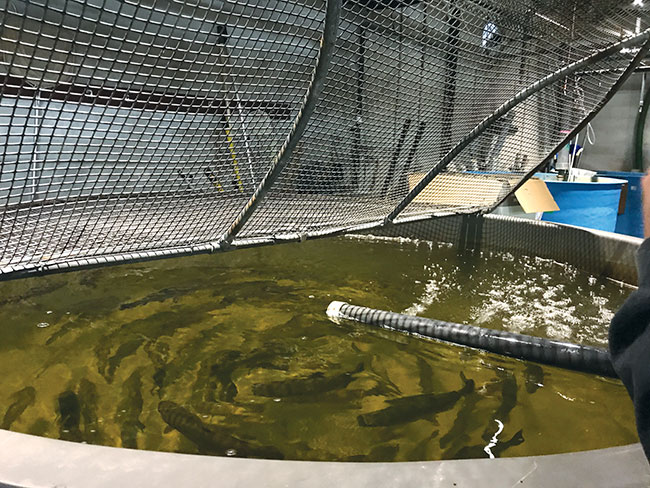

Circular tanks are designed to distribute oxygen throughout the water column to be self-cleaning. With proper inflow setup, tanks should have the look of a gentle whirlpool, sucking used water and solids around and around until it reaches the centre drain.

The rate at which the water travels in a circle within the tank is known as spin rate. Spin rate does not affect the rate at which water enters or exits the tank, it is only how fast the water is traveling around. The spinning effect provides fish with current and can be adjusted by moving the inflow water angle.

For trout or salmon, fish will point themselves into the current (spin) and, when at rest, each fish will have its own little space in the school. The overall effect is good distribution of fish within the tank and even conditions throughout.

Choosing the right spin is a matter of observation. For trout and salmon, about 1.5 fish lengths per second is a good starting point but fish observation is essential. Tank spin shouldn’t make the fish struggle against the current but allow them to keep station easily.

Inflows and Short Circuiting

A tank is known to short circuit when its spin rate is set poorly, and the whirlpool water pattern breaks down. No longer is water travelling a nice circle, the water pattern is erratic and not uniform.

Certain parts of the tank will develop dead spots where the water doesn’t mix. When this happens, usually one will see oxygen decrease drastically in the tank, fish distribution will not be uniform and solid waste begins to accumulate. The vortex over the drain can be seen to migrate around the center drain instead of being fixed over top.

Generally, short circuiting occurs when the inflow(s) are not angled properly, which is more common in tanks with more than one inflow pipe. Inflow should be aimed at the tank wall to ensure the best “push” around the outside of the tank. Pointing the inflow towards the center of the tank will create short circuiting.

Aiming the inflows at the tank wall at 45 degrees is a good starting place when setting the spin. If there are two inflows, try to keep their angles even so they are working together. Inflows should be set up with vertical spray bars to ensure water is injected throughout the water column and to ensure dissolved oxygen in the line is not lost to the atmosphere before it is exposed to the water. This ensures the entire water column is moving evenly. Horizontal spray bars can also be added to the inflow depending on application.

Raceways and Troughs

Though not set up the same as circular tanks, long tanks like raceways and troughs still have the same considerations of flow to maximize water quality. Flow rate is still equally important and provides necessary turnover. Spin rate is not a consideration as the water velocity is determined by the flow rate going through the raceway.

Dead zones are generally non-existent in raceways and troughs but there are water quality considerations regarding flow. Because of the long nature of the raceways, water quality degrades the further the water travels from the inflow. Flow must be maintained to provide acceptable water quality at the end of the raceway or trough, where the water quality is poorest, not just the head or middle sections.

Farmers overcome this shortcoming by injecting oxygenated water at different points along the raceway to boost the water quality, or use air stones to inject oxygen straight into the water. Self-cleaning of the tank bottom isn’t as thorough as in a circular tank and waste feed and feces can accumulate on the bottom.

Some sites will fix inflows strategically along the length of the raceway with the aim of pushing waste along to the end with the extra current. Most sites, however, will simply opt for frequent cleaning and vacuuming up waste to maintain good water quality in raceways and troughs.

Print this page