Features

Recirc

Keys to energy efficiency in RAS

Following the first part of the series of four articles based on the use of energy in recirculating aquaculture systems (RAS), the question is whether or not we measure energy consumption and how. Is the energy consumed within the system monitored? Do we know where in the system it is mostly consumed? Which factors are affecting such consumption?

December 12, 2018 By Maddi Badiola

Aquaculture and RAS are growing dramatically, requiring resources such as land, water and energy. Land and water are finite resources, while energy is not destroyed or created, but transformed. The problem arises when the use of resources for energy transformation goes beyond the limits, becoming unsustainable. Energy use and its associated cost and environmental impact are dependent on several factors like species in production, rearing water temperature, climate and system configuration/design or layout and management. For example, temperature maintenance, depending on the species, can lead to more or less consumption. Local temperature requirements can dictate the overall energy use. Chilling rearing water, for example, is extremely energy intensive so the selection of appropriate devices – properly designed and cost-effective – is pivotal for success. Devices can include energy recovery heat exchangers. These require energy expert cost analysis.

RAS needs continuous energy and its design has implications on the overall efficiency and energy use. Each RAS is different and the technology used in the water treatment loop differs between systems. Operations requiring energy use in RAS and the overall energy requirement will be determined by engineering and operational criteria. Several equipment and processes require energy for water treatment (i.e. water circulation, filtration, biofiltration, oxygenation, temperature control, disinfection) and other activities such as feeding (if automated).

Real data

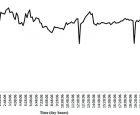

Different methods are used to determine the overall energy consumption of a system, but without any doubt an energy audit will provide the most real and accurate data. In RAS, on-site energy consumption is variable not only daily but hourly, by minute. It follows a time-based pattern consumption (see diagram 1). So, with such fluctuation, how do we provide a detailed recording of continuous energy flow? Through an energy audit; providing real data (i.e. system-specific) and estimating the energy consumption of a given system throughout a given period. Moreover, the energy audit could proffer the energy model of the system under study by showing the energy consumption pattern of each device forming the system. At the same time, they could help reduce fuel use and electricity costs, and increase predictable earnings to the company, especially in times of high energy price volatility.

Easy does it

An energy audit will not alter the production nor disrupt the operation. It requires five easy steps: (I) identification of energy consuming devices and factors affecting consumption fluctuation; (II) installation of energy measuring equipment; (III) energy monitoring; (IV) data collection, assessment and analysis; and (V) diagnosis (see diagram 2). If the facilities and systems are being designed and constructed, energy measuring systems can be integrated within the technology. If not, portable energy logger systems can be used.

Advantages

Energy used in a RAS unit has one of the largest environmental and economical impacts, compared with feed, oxygen or juvenile production. In addition, by using large amounts of fossil energy sources, RAS industry increases, among other things, the Global Warming Potential or CO2-eq. Nevertheless, throughout production, variation of the impacts is notorious. Our study found that energy use varies considerably between different periods during the production process, highlighting the importance of having time-based energy consumption information throughout the production cycle. Such energy quantification helps determine when possible energy saving measures can be applied with effective results. An example is the use of frequency controllers (used to change the frequency and magnitude of the constant grid voltage to a variable load voltage. They are shown to help reduce the electricity consumption of pumps; their efficiency is mainly dependent on the number of starts-stops and required water flows. An average of 20 per cent of the consumed energy could be saved this way.

Energy-efficiency plan

Measuring energy consumption along the production cycle through an energy audit, differentiating consumption peaks, can help in the design on an energy-efficiency plan. This plan should include several renewable energy alternatives and energy saving measures. Good practices, both in the design and management of the systems, would aid in: a more energy efficient framework; reducing energy losses; and (adapting existing systems to reach their potential. Furthermore, the system’s engines, pumps and lighting configurations, as well as thermal equipment’s isolation, all contribute to good practices in RAS design, operation and management. The employees’ ability to understand the system and respond to issues effectively is also vital for efficient management and operation.

By using more energy-efficient systems (together with a proper business plan and designed system), species selection may be done based on market demands, instead of prevailing environmental conditions. This will determine whether such demand can be met at expected market prices while keeping the business profitable.

Measure it continuously if you want to decrease environmental impacts and monetary costs. Engage an expert energy consultant in order to start saving money.

Maddi Badiola, PhD, is a RAS engineer and co-founder of HTH aquaMetrics LLC, (www.hthaqua.com) based in Getxo, Biscaye, Basque Country, Spain. Her specialty is energy conservation, life cycle assessments and RAS global sustainability asessments. Contact her at mbadiolamillate@gmail.com.

Print this page