Features

Recirc

Research

Technology

Denitrifying woodchip bioreactors for wastewater treatment

Results of recent research from The Conservation Fund Freshwater Institute

February 28, 2020 By Christine Lepine, Laura Christianson, Gregory McIsaac and Steven Summerfelt

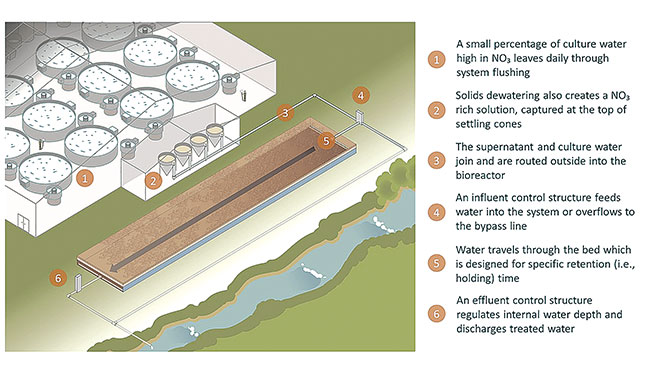

Denitrifying woodchip bioreactor application at a recirculating aquaculture facility (Image courtesy of The Conservation Fund Freshwater Institute)

Denitrifying woodchip bioreactor application at a recirculating aquaculture facility (Image courtesy of The Conservation Fund Freshwater Institute) Recirculating aquaculture systems (RAS) accumulate high concentrations of nitrate-nitrogen (NO3-N) from deliberate and vital nitrification and waste solids dewatering processes, yet the industry lacks cost-effective treatment options for these dissolved waste streams.

Nitrate remediation is essential to RAS facilities that are regulated by nutrient discharge limitations and will be instrumental in maintaining sustainable industry expansion. Recent investigations have suggested that denitrifying woodchip bioreactors, a biologically driven NO3-N remediation technology developed for agricultural systems – where woodchips supply both carbon substrate and surface area for attachment of denitrifying bacteria – may also be applicable for the treatment of aquaculture discharge (Fig. 1).

The bioreactor, an engineered trench filled with inexpensive and easily accessible woodchips, is highly efficient at passively converting nitrate into chemically unreactive atmospheric gas through the denitrification (nitrate reduction) process. Naturally occurring bacteria, called denitrifiers, encounter anoxic conditions within the system, and as oxygen becomes unavailable, they shift from aerobic to anaerobic respiration. As nitrate-laden water filters through the woodchips, it makes contact with the bacteria which utilize the available nitrates instead of oxygen. A stepwise redox reaction continually oxidizes nitrogen species through intermediate forms – nitrate nitrite nitric oxide nitrous oxide di-nitrogen gas – ultimately leaving farmers with remediated water.

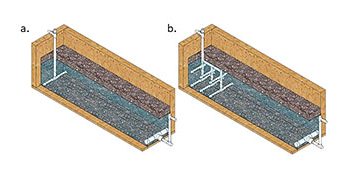

Figure 2

Wastewater treatment with bioreactors

The Conservation Fund Freshwater Institute (FI), based in Shepherdstown, WV, USA, previously demonstrated that pilot-scale woodchip bioreactors were capable of reducing initial NO3-N concentrations in RAS wastewater (70-80 mg/L NO3-N) by 45-99 percent, dependent on retention time. However, observations from these experiments demonstrated certain challenges for adapting this technology for the aquaculture industry. Treatment of wastewater, high oxygen demand (e.g., carbonaceous biochemical oxygen demand or chemical oxygen demand) and waste solids, may cause premature bioreactor failure. For example, bioreactor clogging was apparent as particulate matter and bacterial growth infilled pore spaces between the woodchips near inflow sites, altering flow hydraulics, and potentially reducing nitrate removal efficiencies.

Several aquaculture facilities have recently installed bioreactors, although there is still much to be learned about bioreactor design and management. The successful application of bioreactors at a commercial scale is dependent on continued research for adapting and optimizing bioreactor design for aquacultural use. FI recently evaluated an engineering design modification, in the form of alternate inflow structures, to improve bioreactor performance and reduce system clogging.

Inflow distribution manifold comparison

A recently published “open access” article in Aquacultural Engineering detailed research evaluating bioreactor’s inflow distribution manifold design. Four pilot-scale bioreactors (L x W x D; 3.8 x 0.76 x 0.76 m) with control and experimental manifolds were operated for 784 days, with each manifold design replicated in two bioreactors. The manifold designs, a conventional single straight tee distribution manifold (Fig. 2a, control) and a multiple-header consisting of six times the potential inflow sites (Fig. 2b, experimental), represented both standard-use and an exaggerated design to ascertain if manifold style can influence or extend bioreactor performance by reducing inflow clogging.

For the initial 630 days of operation, the manifold design did not significantly impact bioreactor treatment of wastewater (i.e., bioreactor inflow) produced under FI’s typical operating conditions. Regardless of manifold design, nitrate removal efficiency ranged from 60 ± 1.6 to 80 ± 1.2 percent, dependent on inflow water temperature, while total suspended solids removal efficiency was steady at 92 ± 0.5 percent.

Towards the end of the second year of operation (starting around day 637), the multiple manifold began to outperform the single manifold, with an approximately 11 percent and 12 percent increase in nitrate and suspended solids removal efficiency, respectively. This change in bioreactor performance coincided with a change in inflow water quality, as the bioreactors experienced a period of elevated total ammonia nitrogen, chemical oxygen demand, and total suspended solids in the wastewater. The water quality change occurred during a period of atypical operating conditions at FI, resulting in a longer holding time in settling cones and supernatant holding tanks and increased mineralization of the wastewater before it entered the bioreactors. Differences in manifold performance could not be attributed to inflow water quality, as both manifold designs were subjected to the same change.

Neither bioreactor design reached a failure point, i.e., where plugging in a bioreactor would cause the water level to rise above the bed of woodchips, after two years of operation (784 days), indicating aquaculture wastewater treatment in woodchip bioreactors is viable longer than previously evaluated. Both designs kept bioreactors operating without excessive clogging over the extended study period, demonstrating < 4 cm of water head loss was produced across each reactor and approximately 17-25g removal of NO3-N m-3 d-1 (from treating 49-52 mg NO3-N/L inflow) during their second year of operation. The multiple manifold design may extend the bioreactor lifespan, but further study is needed to determine the failure point for each manifold style as well as alternative bioreactor designs.

Note: For a list of references cited in this article, please email the editor

mdeguzman@annexbusinessmedia.com

Print this page

Advertisement

- Aquatic ED now offers FIAP products

- Feed challenges threaten aquaculture gains in Sub-Saharan Africa