Features

Recirc

Systems management

Technology

Understanding depuration

Practical implications for reuse or discharge at RAS facilities

November 10, 2022 By John Davidson

Figure 1. Partial reuse depuration system with 18 m3 culture tank and gas conditioning tower (on the right).

(Photo: Freshwater Institute)

Figure 1. Partial reuse depuration system with 18 m3 culture tank and gas conditioning tower (on the right).

(Photo: Freshwater Institute) Depuration is a proven finishing process that eliminates earthy, musty off-flavour from RAS-produced salmonids and other fish species before they are harvested and sent to market. This relatively simple procedure, alternately referred to as “purging,” begins with transfer of market-size fish from RAS grow-out tanks to flow-through or partial reuse systems.

First use water lacking the common off-flavour compounds geosmin and 2-methyisoborneol (MIB) is rapidly exchanged while withholding feed. Depurating fish subsequently eliminate off-flavour across the concentration gradient with the passing water. Although depuration is effective when specific procedures are applied, there are disadvantages to the process including a requirement for significant water use (Davidson et al., 2020). Nevertheless, several RAS facilities have adapted to this challenge by repurposing depuration system effluent as supply water for recirculating systems.

The premise for this application assumes that fasting fish excrete minimal waste products during the purging process, resulting in a high-quality effluent that can be reused. Until recently, however, depuration system water quality had not been characterized, and the implications of its reuse or discharge were not fully understood. Therefore, researchers at the Freshwater Institute (FI) thoroughly assessed water chemistry and waste production metrics in a depuration system fully stocked with market-size Atlantic salmon. A comprehensive article describing this research was recently published in the Journal of the World Aquaculture Society (Davidson et al., 2022). The most important findings are summarized herein.

Study design & methodology

Atlantic salmon were cultured to market-size in six identical freshwater RAS. Once the fish were ready for harvest, depuration procedures were initiated by pre-cleaning and disinfecting a designated partial reuse system with an 18 m3 dual-drain culture tank (Fig. 1). Continuous spring water addition was then established resulting in complete replacement of the system volume 7-8 times per day, and feeding was discontinued in the six RAS one day before relocating fish.

The next day, 311 salmon weighing 5-6 kg were removed from the RAS and stocked in the depuration tank at a commercially relevant density of 100 kg/m3. The salmon were purged over a seven-day period following proven procedures developed by FI researchers. To characterize depuration system water quality, samples were collected every six hours via grab sample or use of a programmed autosampler.

Subsequent testing was carried out in FI’s Water and Environmental Chemistry Lab for total suspended solids (TSS), total phosphorus (TP), and total ammonia nitrogen (TAN), among other parameters. In addition, dissolved oxygen (O2) and temperature were continuously monitored via a Hach SC100 system. Gas flow to a low head oxygenator was regularly adjusted to maintain >100% O2 saturation in the depuration tank.

Important water quality trends

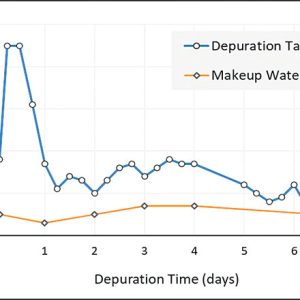

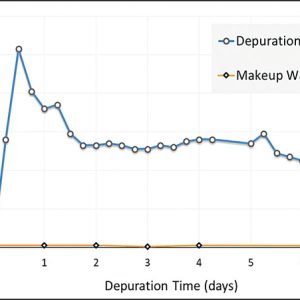

Immediately after stocking, TSS, TP, and TAN concentrations spiked indicating that the salmon continued to excrete residual wastes despite 24 hours of prior feed deprivation. Over the next six days, TSS (Fig. 2) and TP levels gradually declined, approaching concentrations similar to the makeup water. On the contrary, TAN levels plateaued suggesting that salmon began to catabolize somatic tissue in the absence of dietary nutrition (Fig. 3). The change in concentrations between the depuration tank water and the makeup water ranged as follows during the seven-day period: 0.4–3.5 mg/L TSS, 0.015–0.200 mg/L TP, and 0.42–1.02 mg/L TAN.

Implications for water reuse

Results from this study provided a wealth of practical knowledge for reusing depuration system water in RAS. First, the spike in waste concentrations measured immediately after stocking confirmed that one day of preliminary feed withdrawal is not sufficient to clear the gastrointestinal tract of market-size Atlantic salmon (Einen et al., 1998) before depuration. Land-based salmon producers could therefore adopt a two or three-day feed withholding period before moving fish to purge systems, which would allow most of the waste excretion to occur in the original RAS. These data also suggest that when depuration system water is introduced within RAS, it should be added before a solids removal process like a microscreen drum filter.

With this strategy, remaining solids would be rapidly removed thereby reducing the potential for particle breakdown, inhibited nitrification, and other negative impacts that solids have on system performance and fish health. In addition, because most of the measured TP in the depuration system water was likely contained within residual suspended solids, much of that phosphorus would also be removed by the drum filter. Moreover, the trend for continuous TAN production validates the recommended location for introducing depuration water in RAS, because biofiltration typically follows solids removal processes in the water treatment sequence.

Important lessons related to O2 management and carbon dioxide (CO2) control were also gleaned when depurating Atlantic salmon at relatively high density. For example, during the stocking process, Atlantic salmon consumed greater amounts of O2 due to mild handling stress and increased gill ventilation rate. Over the next six days, oxygen consumption gradually declined as salmon acclimated to the depuration system environment. Fish production managers could prepare for these dynamic oxygen requirements by supersaturating depuration system water with O2 before stocking fish and by making frequent gas flow adjustments at the oxygenator. Setpoints for backup O2 systems could also be adjusted to periodically diffuse extra oxygen to maintain safe O2 levels in the depuration tank at such high densities. Lastly, maintenance of safe CO2 concentrations of 10 mg/L at high salmon density further validated a suggested requirement to exclude water aeration media from depuration systems (Davidson et al., 2014).

In addition to these practical takeaways, the reported waste production data are also beneficial for mass balance calculations used to determine required flow rates across water treatment devices such as biofilters and oxygenator units; therefore, the published data provide relevant information for RAS engineers designing land-based Atlantic salmon facilities.

Implications for facility discharge

Water quality and waste production results from this study are also relevant to salmon RAS facilities that plan to discharge depuration system water, particularly in localities with relatively stringent pollution elimination requirements. Although waste production was generally low in the depuration system, solids and nutrients were still released by the fish. These waste concentrations would contribute, in part, to cumulative effluent levels at a RAS facility. During the seven-day depuration period, cumulative waste discharge from the depuration system ranged as follows: 0.14–0.55 kg TSS/day, 0.004–0.029 kg TP/day, and 0.060–0.109 kg TAN/day. It is important to note that these metrics should be considered with specificity to the study conditions including system flushing rate, biomass density, and background concentrations of the makeup water.

Off-flavour

Although this study was focused on water quality and waste production in depuration systems, off-flavour levels were also assessed in water and fish flesh. Average geosmin and MIB levels were < 4 ng/L in the original RAS over the eight-month period that preceded this study, and salmon fillet concentrations were < 100 ng/kg when the fish were removed for purging. Therefore, these salmon may have been “on-flavour” before the depuration process began. FI scientists and collaborators are actively assessing the cumulative conditions that limited off-flavour production including RAS water quality and system microbiome.

References:

- Davidson, J., Schrader, K., Ruan, E., Swift, B., Aalhus, J., Juarez, M., Wolters, W., Burr, G., Good, C., & Summerfelt, S.T. 2014. Evaluation of depuration procedures to mitigate the off-flavor compounds geosmin and 2-methylisoborneol from Atlantic salmon Salmo salar raised to market-size in recirculating aquaculture systems. Aquacultural Engineering 61, 27–34. https://doi.org/10.1016/j.aquaeng.2014.05.006

- Davidson, J., Grimm, C., Summerfelt, S., Fischer, G., & Good, C. 2020. Depuration system flushing rate affects geosmin removal from market-size Atlantic salmon Salmo salar. Aquacultural Engineering 90, 102104. https://doi.org/10.1016/j.aquaeng.2020.102104

- Davidson, J., Redman, N., Crouse, C., & Vinci, B. 2022. Water quality, waste production, and off-flavor characterization in a depuration system stocked with market-size Atlantic salmon Salmo salar. Journal of the World Aquaculture Society, early view. https://onlinelibrary.wiley.com/doi/epdf/10.1111/jwas.12920

- Einen, O., Waagan, B., & Thomassen, M.S. 1998. Starvation prior to slaughter in Atlantic salmon (Salmo salar) I. Effects on weight loss, body shape, slaughter- and fillet-yield, proximate and fatty acid composition. Aquaculture 166, 85–104. https://doi.org/10.1016/S0044-8486(98)00279-8

Print this page