Features

Research

Weaning Diets — Small particles, Big impact

September 13, 2016 By Diogo Thomaz

Though a tiny part of overall production costs

Though a tiny part of overall production costsAnyone that has been involved in the sale and promotion of larval and weaning feeds for marine fish species has faced the difficulty of justifying the cost of these products to their customers. This is especially true when the customer is an integrated company with hatcheries and growout sites; the temptation is always to compare the price of 1kg of a weaning diet to that of 1kg of a growout feed.

They are completely different products however, that use different raw materials, different production methods, that result from years and years of research and technology development.

At growout stages fish have fully developed digestive systems that can take almost any formula (within reasonable limits) and absorb some of its nutrients for growth. Of course there are issues of efficiency in the use of ingredients and this is what makes one formula better than another.

The larval difference

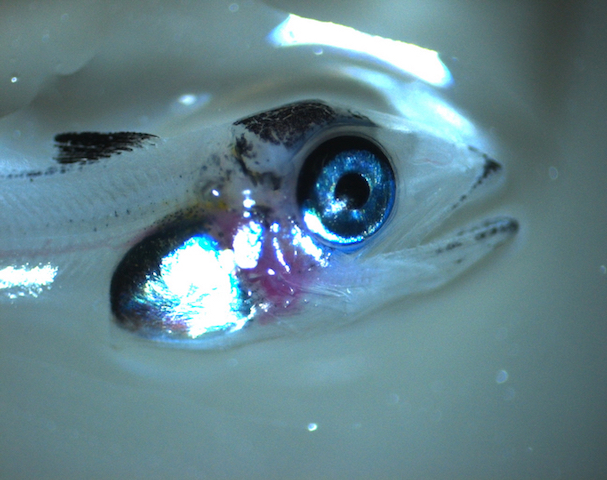

Larvae of marine fish hatch with a very limited set of digestive enzymes and are extremely difficult to satisfy. Also they eat very slowly and are exposed to the surrounding aquatic environment.

Larval diets need to be very stable in water so they don’t pollute the environment and at the same time are easily digested in the gut of larvae once they are eaten. These are almost contradictory requirements. Apart from this the nutritional composition of larval diets must supply all the requirements for a fish that is growing at rates of up to 10-20% per day. If any key micro-nutrient is missing the diet will not perform.

The cost of this technology, the components, and the completely different dynamics of production of larval diets (where a batch can take weeks to produce as opposed to the 8-10 tons/hour for an extruder producing growout feeds) make up for a completely different product (and price) compared to growout feeds.

Where are we today?

Today the largest slice of the market for weaning diets for marine species is the 1-1.2 billion bass and bream fry produced in the Mediterranean region. Other regions are growing quickly however, with dozens of marine fish species produced in Asia, the Middle East and more recently in Central America.

Marine fish species represent one of the fastest growing sectors in global aquaculture and with the increase in purchasing power of the middle classes in many Asian countries this will soon become a big slice of global aquaculture production.

The bass and bream market is well supplied (perhaps over-supplied…) with a number of weaning diets, many of excellent quality, that allow companies to achieve very good performances in terms of survival and quality of fry.

New species and industrialization of their hatchery production is probably the number one challenge for many larval nutrition companies and where a significant number of research and development projects are now focused. The transfer of know-how from countries such as those in the Mediterranean basin, where fry production of marine species has reached an almost optimal level, is a way to accelerate development of this industry in other parts of the world.

Performance drivers

What should we aim for with a good weaning diet? Even if we use the most expensive weaning diets available in the market today the contribution of their cost to the total cost of production for commercial-sized fish is very, very small.

For the bass and bream industry where I have clearer numbers, weaning diets account for less than 1% of all production costs, and in these species you use 4-5 fry to produce 1kg of fish (commercial size is 300-400g). In species that are sold at larger sizes the cost of fry (and weaning diets) is proportionally even smaller.

Weaning diets, however, can have an incredible leveraging effect of the overall costs of production, both in the hatchery and in the on-growing stages.

The key driver of cost performance in hatcheries is the number of weaned fry you get per production tank. This is a function of the tank sizes but mainly of the survival of larvae during the weaning stages. Doubling survival halves your costs, more or less.

Another important driver is the length of the production cycle and here growth rate, also a function of weaning diet quality, can allow you to produce more – if you have fast rates – or less – if slower production cycles per year.

The impact of weaning diets in the growout stages is often ignored but my experience has shown it to be very important. The nutritional quality of a weaning diet (and of the nursery diets used) can mean that you stock growout tanks or cages with healthy, fast growing fish or with fish that are physiologically compromised, with sick livers and with digestive tracts that cannot perform.

I remember having participated in research projects at the company for which I worked where we looked at the histology of sea-bream fry weaned on different diets and found enormous differences in the fat levels in the liver, some showing signs of cirrhosis even at that early stage. It would be interesting to follow the performance of that fry in growout but I bet it would not be excellent.

— Diogo Thomaz

INTERVIEW BY DIOGO THOMAZ

Weaning Diets – A Researcher’s View

Hatchery International’s Mediterranean correspondent interviews Luís Conceição, the CEO and R&D director at Sparos about the challenges of developing effective weaning diets for marine species.

Luís Conceição is a friend and colleague and one of the worlds’ experts in larval nutrition for

marine species. He is CEO and R&D director at Sparos Limited, has coordinated several research projects and PhD students in fish larval nutrition at Sparos and at CCMAR, a research center belonging to the University of the Algarve in Portugal. Luís was also vice-chair of the EU’s COST action Larvanet (2008-2013), one of Europe’s main research networks focused only on the production of fish larvae.

I know that Sparos has been tackling some important problems facing the weaning of new species in aquaculture and took the opportunity to ask him a few questions about the status and challenges facing this industry.

Thomaz – Do you think that the main marine species farmed today (bass and bream in the Mediterranean) require further work in terms of weaning and post-weaning diets?

Conceição – Yes, I believe that the weaning diets currently used can still be significantly improved. This will help reduce the skeletal abnormalities problems that are still observed in bass/bream hatcheries, and will also lead to faster larval growth and improved quality of the juveniles. This was one of the main conclusions of the COST action Larvanet, resulting from discussions among European researchers and hatchery managers over a period of three years. We still know little about the nutritional requirements of bass and bream, and fish larvae in general. These improvements can be both at the levels of nutrition and microdiet production technology. More research and new microdiets are certainly needed. The challenge is to have better products that have an affordable cost for the industry. They will tend to be more expensive to cover for higher ingredient costs, production technology and R&D costs. These new microdiets will need therefore to be evaluated in terms of their cost-benefit.

Thomaz – The EU research program Diversify is looking at alternative species to those currently being farmed; some of these are marine species like the Meagre or the Yellowtail. Can these species be weaned with existing diets? Is the industry looking for something new in this area (larval nutrition)?

- – Yes, species such as meagre or the yellowtail/amberjack can be weaned on some of the better current products in the market. Meagre seems to be easier in this respect, with good growth and survival results despite some problems with cannibalism. For amberjack/yellowtail weaning is more difficult with current weaning diets, with significant losses to cannibalism. Therefore, if weaning diets currently used in bass/bream can still be improved, it’s more so for species with faster growth rates such as meagre and yellowtail. Most likely there will not be a one-diet-fits-all; especially when one evaluates their cost-benefit. Probably it will be much easier to accommodate a higher-quality-higher-price diet for amberjack/yellowtail than for bass/bream. Also the nutritional requirements of each species are most likely to be different. I believe the industry is aware of all this, and is indeed looking for something new, especially for the new species.

Thomaz – What would you say are the main challenges from the technical, scientific and production points of view, for the development of better weaning diets for existing and new species?

- – The challenges are many, but I believe that with some coordination between the researchers and the industry these can be largely overcome in an affordable way.

From the technical point of view, the main challenge is to make a small particle which is water stable, but easily digestible. Several technical solutions are available for this using for instance microencapsulation, but most are too expensive. Some also bring challenges for up-scaling from the lab to production. The main scientific challenge is the lack of precise knowledge on larval nutritional requirements. Overall the real challenge is how to finance the necessary R&D effort. The market volume for weaning microdiets is relatively small, and no single company can fund on its own the necessary R&D effort for a full programmed. There will need to be some public funding for this, especially in larval nutritional requirements. This makes sense since the benefits of improving larval quality for the aquaculture industry as a whole would certainly largely exceed the necessary costs of a few million euros.

At Sparos researchers have been working on agglomeration and other techniques to produce weaning diets that target new species such as the sole, bluefin tuna and the yellowtail.

Diogo Thomaz, PhD, MBA, is a Technical and Business Consultant for the Aquaculture Industry, based in Athens, Greece. After 15 years as R&D project manager and other industry positions he now leads Aquanetix (www.aquanetix.co.uk), a business intelligence service for the global aquaculture industry. He also heads RealSales Ltd a sales and technical consultancy company that supports aquaculture businesses expand opportunities and markets. He can be contacted by email on diogo@aquanetix.co.uk

Print this page

Advertisement

- Rapid test for seawater readiness the focus of Scottish research

- Willow Beach National Fish Hatchery relaunches trout program